Industrial Water Purification Systems - Our Services

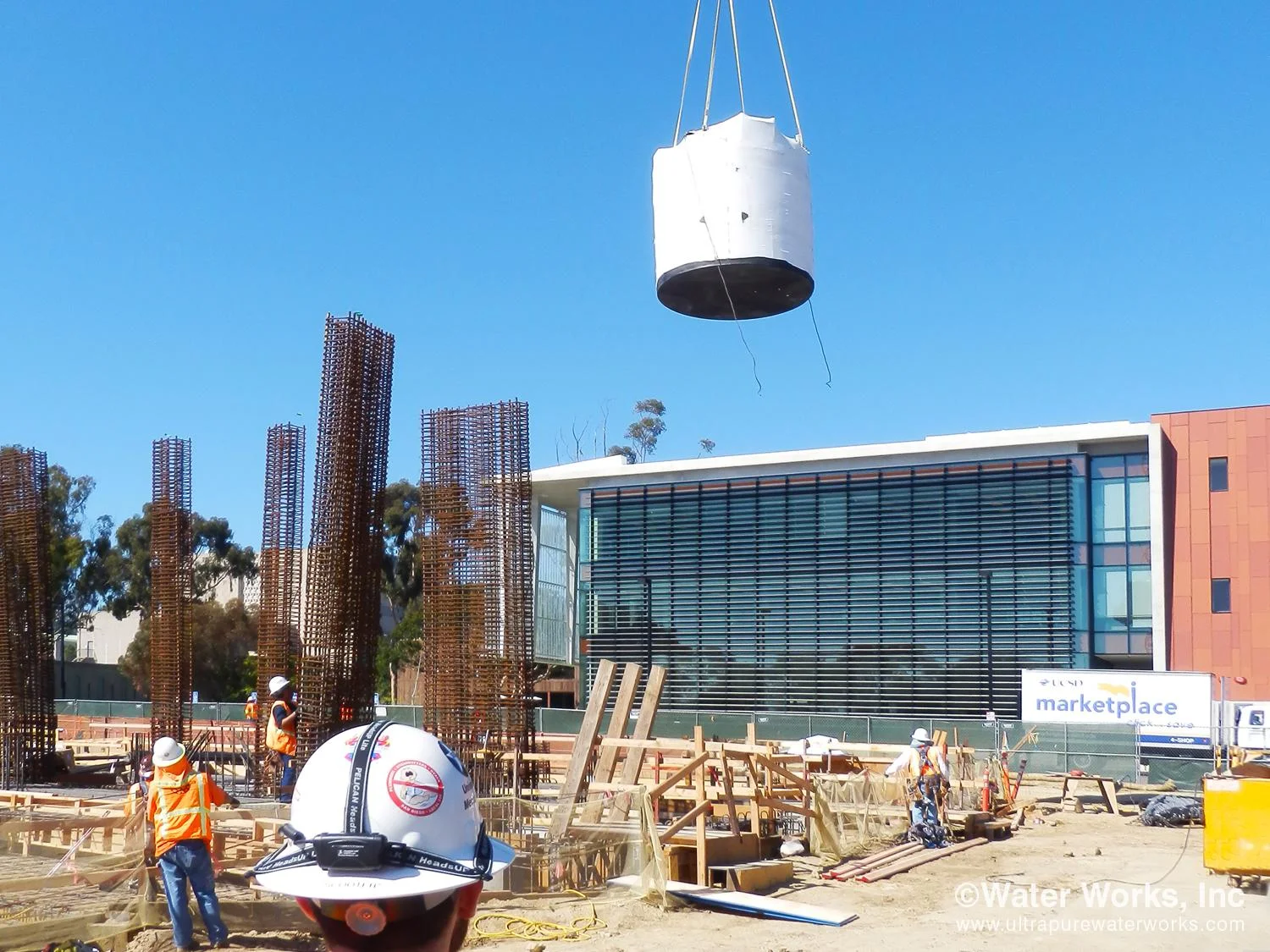

Water Works, Inc. is a fully integrated manufacturer and service provider for industrial ultrapure water systems for the Life Science and other high tech industries.

Our customers include top medical hospitals, pharmaceutical GMP manufacturing facilities, research labs, universities, and research institutions.

Water Purification System Types

BY PURIFICATION PROCESS

RO (reverse osmosis system)

DI (deionized) Water

Water Softening

Ultrafiltration and Nanofiltration

UV Sterilization

Electrodeionization (EDI)

Ozonation

Advanced Oxidation Process (AOP)

SPECIAL APPLICATIONS AND QUALITY STANDARDS

Low TOC water for liquid chromatography (LC), Mass spectrophotometry (MS), HPLC, PCR

Nuclease and endotoxin free water for PCR, Sequencing and Microbial Applications

ASTM type 1, 2, 3 water.

CAP, National Clinical Chemistry Lab Standards (NCCLS)

CLRW (clinical lab reagent water) - Diagnostic Companies

USP Purified Water (Purified Water and Water For Injection (WFI))

E1 Grade Water Generation (Highest Purity Water - Semiconductors).

DESIGNING CUSTOM SYSTEMS TO FIT YOUR NEEDS

During the process of developing design specifications, Water Works engineering team works closely with customers and Architecture and Engineering (A&E) partners to evaluate and document user needs in User Required Specifications (URS) /User Defined Requirements (UDR).

In accordance with industry best practices, the final design specification package includes the full documentation of user needs, and incorporates not only the intended application(s) and site-specific requirements, but also the business objectives (expansion plans, budget, etc).

APPLICATION-FOCUSED SYSTEMS | COMPREHENSIVE PROPOSAL

Our team takes an application-focused approach to engineering industrial water solutions, taking into consideration everything from technical requirements to operational and financial objectives.

Water Works' comprehensive proposal packages cover all the operational dimensions across the full life cycle of the system, from P&ID (Process and Instrumentation Drawing), 3D CAD models, and BIM-compatible dimensional drawings all the way to the general arrangement, installation, preliminary project schedule, operating budget, documentation plan and much more.

QUALITY PARTS | ADVANCED TECHNOLOGIES | LOCAL

We are proud of our track record – our commitment to manufacturing excellence, strict project management, and customer service has allowed us to become a preferred provider for many California-based businesses and institutions.

We use top quality materials and advanced manufacturing practices and technologies. For example, our investment in onsite, high-throughput, cutting edge IR-fusion machines allow us to deliver top quality documented certified welds at each fusion point.

Our engineering team ensures transparency, flexibility, and cost control by using non-proprietary materials and providing detailed supporting documentation on their origin, maintenance schedule, and reordering procedure.

We leverage our position as a fully-integrated San Diego based manufacturer to shorten production time and validation costs by being able to offer onsite Factory Acceptance Testing (FAT) and minimal site presence (with 98% of the work done at our facilities). We are also uniquely positioned to be able to deliver accelerated timelines for customers who request it.

Our commitment to good commissioning procedures and well-planned and documented validation packages allow our customers to minimize the time and the cost of systems validation (IQ, OQ and PQ).

SERVICE | MAINTENANCE | VALIDATION

Water Works offers a full line of service, maintenance, and validation contracts across the full life cycle of industrial water purification systems.

We believe that a partnership with the customer is essential for ensuring the longevity of the serviced system. To this this end, we work with our customers to define operational and performance parameters as well as action and alert limits. This ensures that our rigorous service and maintenance documentation practices are in compliance with the relevant regulatory requirements (FDA, EUDRALEX, ICH).

Our service team is committed to ensuring the highest performance of our serviced systems, and complete compliance with the constantly evolving water quality specifications and standards for all our Life Sciences customers. And while we do have 24/7 emergency service staff available, our key focus is preventative maintenance.

Our expertise in building and servicing industrial water systems for Life Sciences has allowed us to become the preferred provider of scheduled, adaptive, and predictive maintenance for many San Diego based R&D and cGMP facilities.