Water-Saving Cooling System For a cGMP Specialty Pharmaceutical Manufacturing Facility in San Diego, CA

/Water Works, Inc. (San Diego, CA) announces the completion of the new water-wise project - a cooling system for two cGMP pharmaceutical manufacturing facilities in San Diego, CA for a specialty pharmaceutical company focused on the clinical and commercial development of acute care products.

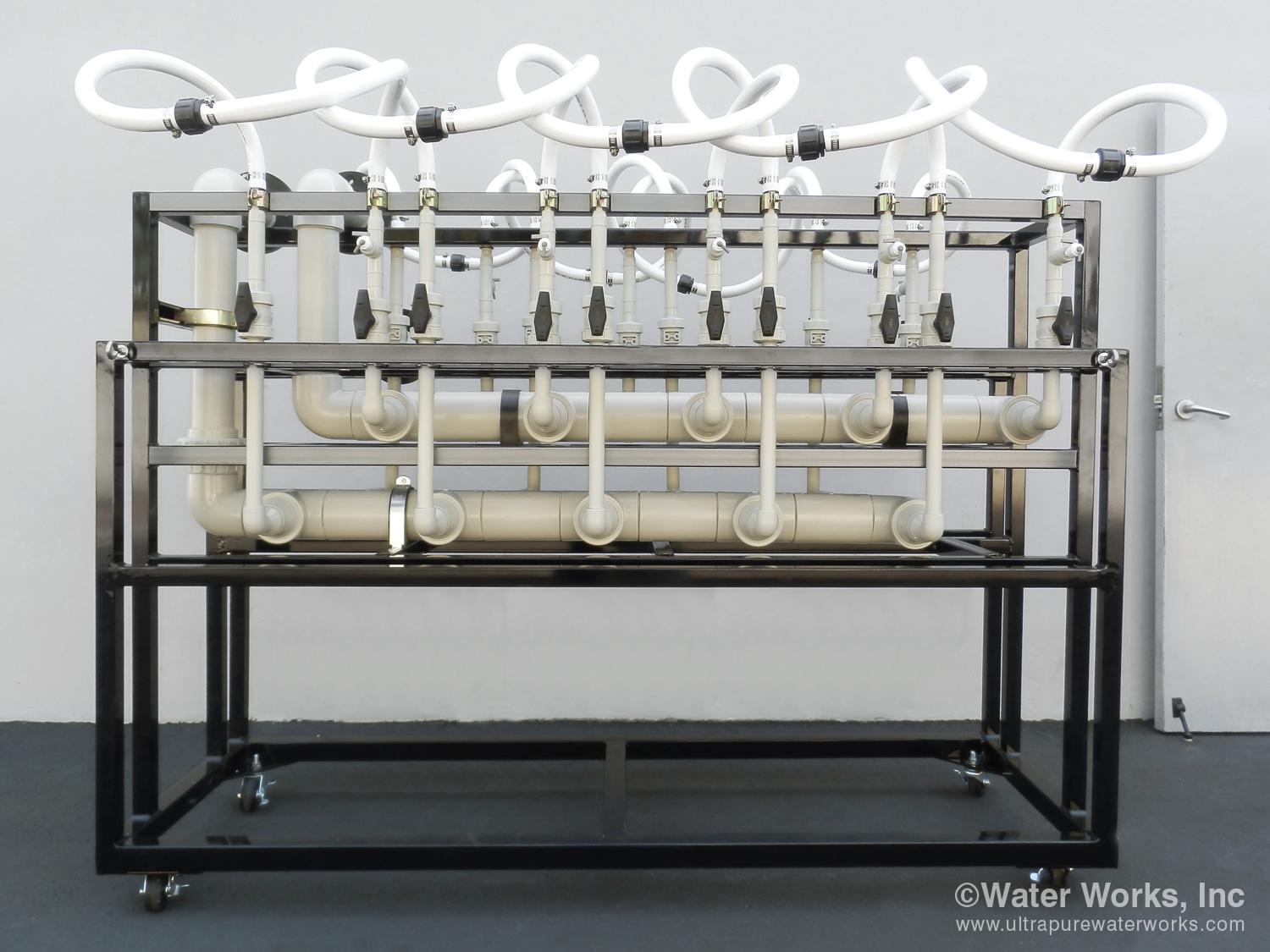

The new deionization (DI) skid replaces the previously installed EDI system to be used in manufacturing of acute care products.

INSTALLATION OVERVIEW

The client was looking for a more robust solution to accommodate increasing demands from a rapidly expanding manufacturing operation while reducing water use.

The Water Works team implemented a water-saving cooling project for the cooling system used in their manufacturing process. Simply switching to the new soft water solution resulted in increased conductivity blowdown cycles (from 3500 micromho to 10,000 micromho), saving more water. The system reuses reverse osmosis (RO) concentrate as one of the water sources for cooling towers, drastically cutting water consumption of the operations.

Implementation of the RO concentrate reuse system for the chilling phase of the manufacturing process reduced water consumption by 4-5 million gallons/year.

CASE STUDY - SUSTAINABILITY

The cooling system feeds three 180 ton chillers (see image 1 below). Only two of the chillers are typically active, with the 3rd acting as a spare for peak summer loads.

The installation uses an innovative monitoring and control system for dynamically selecting water sources for cooling the towers based on water level in the tower. The level controller activates solenoid valves that feed the water sources to the towers. It also doubles as a low-level alarm for any problem with any of the water supply sources.

The system is automated to prefer the use of RO concentrate, when available, to top off cooling water level. In times of high demand, where there is a lack of reusable concentrate, soft water is used to fill the towers.

The system was completed on February, 2015. The preliminary data from the installed water consumption meters report that the towers consumed 575,700 gallons of RO concentrate and 211,00 gallons of soft water over the course of 4 months.